* My article in BusinessWorld, December 8, 2020.

During the BusinessWorld Economic Forum with the theme “Forecast 2021: Reboot, Rethink, Reshape” which ran on Nov. 25-26, the government’s Build, Build, Build program and the construction sector as a path to post-COVID-19 economic recovery were among the topics highlighted. National Economic and Development Authority Director General Karl Chua and Ayala Corp. CEO Jaime Augusto Zobel de Ayala had partly mentioned this.

Meanwhile, during the 9th Arangkada Philippines Forum 2020 with the theme “Foreign Investment in the Post-Pandemic Philippines” held last week (Dec. 1-3), large scale foreign investments of up to $50 billion in 10 years in various sectors including infrastructure, and the Build, Build, Build program were discussed and explored by the various speakers, particularly some of the heads of the Joint Foreign Chambers of Commerce in the Philippines (JFC) like head of US Chamber Peter Hayden and head of the Japan Chamber Keiichi Matsunaga.

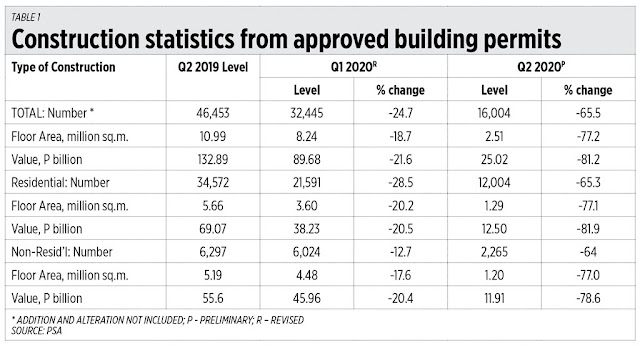

I checked the performance of the construction sector and it turns out that it contracted -77% in floor area and -81% in value in the second quarter (Q2) 2020, worse than overall GDP contraction of -16.9% in the same period, according to data from the Philippine Statistics Authority (see Table 1).

The Philippine Statistics Authority (PSA) also released a survey of establishments 2018, the latest data available. From 2012 to 2018, the share of establishments in basic iron and steel have declined but their employment, total revenues, and output value have increased, meaning that on average there is higher productivity per company in the sector (see Table 2).

So that’s the good news — rising employment, rising productivity in the sector.

The bad news is that there is the issue of dirty production and unsafe steel in the country, partly because of steel smuggling but largely because of the transfer of many steel plants using the induction furnace (IF) technology which was banned by China in 2017. Banned in China, welcomed in the Philippines, not good as seemingly we are the dumping ground of industrial garbage from China.

Before 2016, about five IF plants existed in the country. By 2020 there were already 13. These IF plants’ capacity rose from 0.2 million MT to 1+ million MT/year.

The Philippine Iron and Steel Institute (PISI) says that the IF process “is a ‘hit-or-miss mechanism’ that has no refining process to remove impurities. As such, its output steel is inconsistent in terms of quality and could pose harm to users.”

The ASEAN Iron and Steel Council (AISC) called for the ban of IF in the region, saying the region has become a preferred destination for the “obsolete and unwanted equipment from China.” The Philippines and Indonesia are the big destinations of these IF plants while Vietnam has no more IFs from China since the latter banned the furnaces in 2017, according to the Vietnam Steel Association (See https://www.bworldonline.com/chinas-outcast-steel-machines-find-unwelcome-home-in-se-asia/, Dec. 18, 2018).

The Philippine Induction Smelting Industry Association (PISIA), however, argues that IF steel is clean and safe.

In 2018, the Department of Environment and Natural Resources (DENR) penalized five companies using IF for the alleged violation of the Clean Air Act of 1999 (RA 8749). These were Melter Steel Corp., Real Steel Corp., Wan Chiong Steel Corp., Metro Dragon Steel Corp., and Davao Mighty Steel Corp. (See https://www.bworldonline.com/denr-to-charge-5-steel-mills-for-pollution/, Oct. 29, 2018).

The DENR and the Department of Trade and Industry (DTI) have become strict when it comes to granting permits to new IF plants. But these plants get permits from local government units (LGUs) by under-claiming their production capacity as only 30,000 MT per year. If they declare higher than that figure, their application will go to the DENR and the vetting will be strict.

More competing steel plants selling more steel bars and other iron products are good for consumers — they will have more choices. But ordinary consumers, even many hardware stores, are not aware of the dangers of substandard steel products, or they may be aware but they cannot easily detect these products.

Every year the Philippines get big storms with strong winds, plus we also experience occasional strong earthquakes that can shake entire houses and buildings. Getting cheap steel bars will prove to be more expensive once houses and buildings experience big cracks if not collapse entirely. Conversely, getting higher price steel bars which can withstand strong winds and earthquakes will prove to be cheaper as they can save lives and property.

Given this situation, the DENR and DTI should make

surprise inspections of IF plants that have only LGU permits, even old plants

that got permits from them earlier. Once RA 8749 and other laws on product

safety are violated, these plants should be closed and given a limited appeal

period.

----------------

See also:

BWorld 462, Coal moratorium, climate and flooding, December 03, 2020

BWorld 463, Senator Recto’s tax cut plan shadows Reagan, Thatcher, and Trump tax cuts, December 04, 2020

BWorld 464, Meralco, QPPL and expensive solar-wind, December 05, 2020.

No comments:

Post a Comment